- Home

- Machine Product

- Brushless Motor Production Equipment

- Armature Machine

- Assembling

- Shaft Pressing and Run-out Measurement Machine

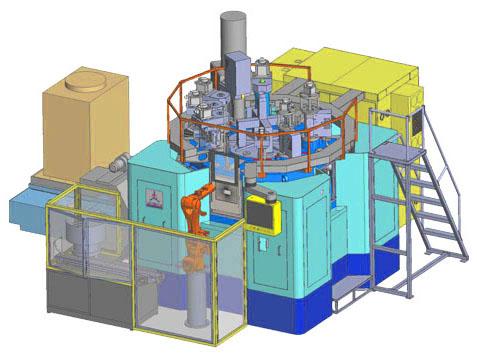

Shaft Pressing and Run-out Measurement Machine

- Mechanical Description

- Film

* Identify the front and back of end cover; turn it over and heat to the set temperature.

* The motor lamination and end cover are put on the fixture in order by manipulator.

* Servo Pressing has real-time monitoring function for full stroke, and also can make curve chart about the stroke and pressure at the same time.

* To reach real-time monitoring, machine can set up to 6 pieces of check Interval; when the pressure curve is over the interval, the system will alarm.

* After pressing, it can Inspect the run-out of shaft. The accuracy is within 1um (0.001 mm).

* Cycle Time: 45 sec./pcs