- Home

- Machine Product

- Production Line

- Steel Wheel Processing Line

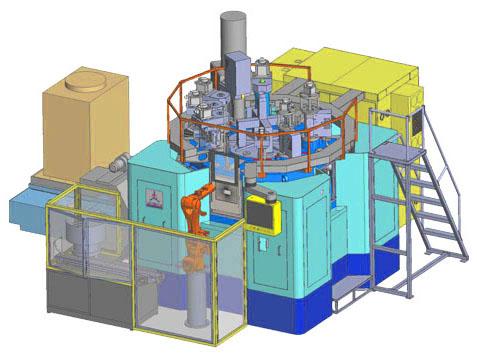

Steel Wheel Processing Line

Steel Wheel Processing Line includes crown, feeding, flat, feeder, stamping, cutting, forming, welding, scrape slag, rolling forming, hemming, air density test, punching, spot welding, measuring and calibration.

Processing Sequence

Popular Product